Leak

Moderators: bohica2xo, Tim, JohnHere

-

tnfarmboy

- Posts: 9

- Read the full article

- Joined: Sat May 28, 2022 5:46 pm

Leak

Hi,

I just replaced the compressor, and condenser, etc on my 2004 Frontier. It wouldn’t hold a vacuum so I put a little freon in and could immediately hear the leak. The high pressure line was loose at the New condenser, I could move it, not a lot, but a little is too much. So, I bought a new low side line with the flange thinking the old one was worn. Well, same thing. The mating surface on the new condenser looks fine, haven’t put a straight edge on it though. At the beginning, I put new O-Rings on both lines, same size, different color, lol. I can’t tell if that flange on the high line is crushed any. Replacing that high pressure line is not feasible. I’ve got some ideas, but they are redneckish. Otherwise, I’m pretty much lost here. Anybody been here? Ideas? I figured that I could post some pics, but they are over 2mb, lol.

Thanks!!

DD

I just replaced the compressor, and condenser, etc on my 2004 Frontier. It wouldn’t hold a vacuum so I put a little freon in and could immediately hear the leak. The high pressure line was loose at the New condenser, I could move it, not a lot, but a little is too much. So, I bought a new low side line with the flange thinking the old one was worn. Well, same thing. The mating surface on the new condenser looks fine, haven’t put a straight edge on it though. At the beginning, I put new O-Rings on both lines, same size, different color, lol. I can’t tell if that flange on the high line is crushed any. Replacing that high pressure line is not feasible. I’ve got some ideas, but they are redneckish. Otherwise, I’m pretty much lost here. Anybody been here? Ideas? I figured that I could post some pics, but they are over 2mb, lol.

Thanks!!

DD

- Attachments

-

- New2.jpg (255.62 KiB) Viewed 3408 times

-

- HighFlange4.jpg (217.63 KiB) Viewed 3408 times

-

- NewHose2.jpg (248.77 KiB) Viewed 3408 times

- JohnHere

- Preferred Member

- Posts: 1555

- Joined: Sun May 13, 2018 10:20 am

- Location: South Carolina Upstate - USA

Re: Leak

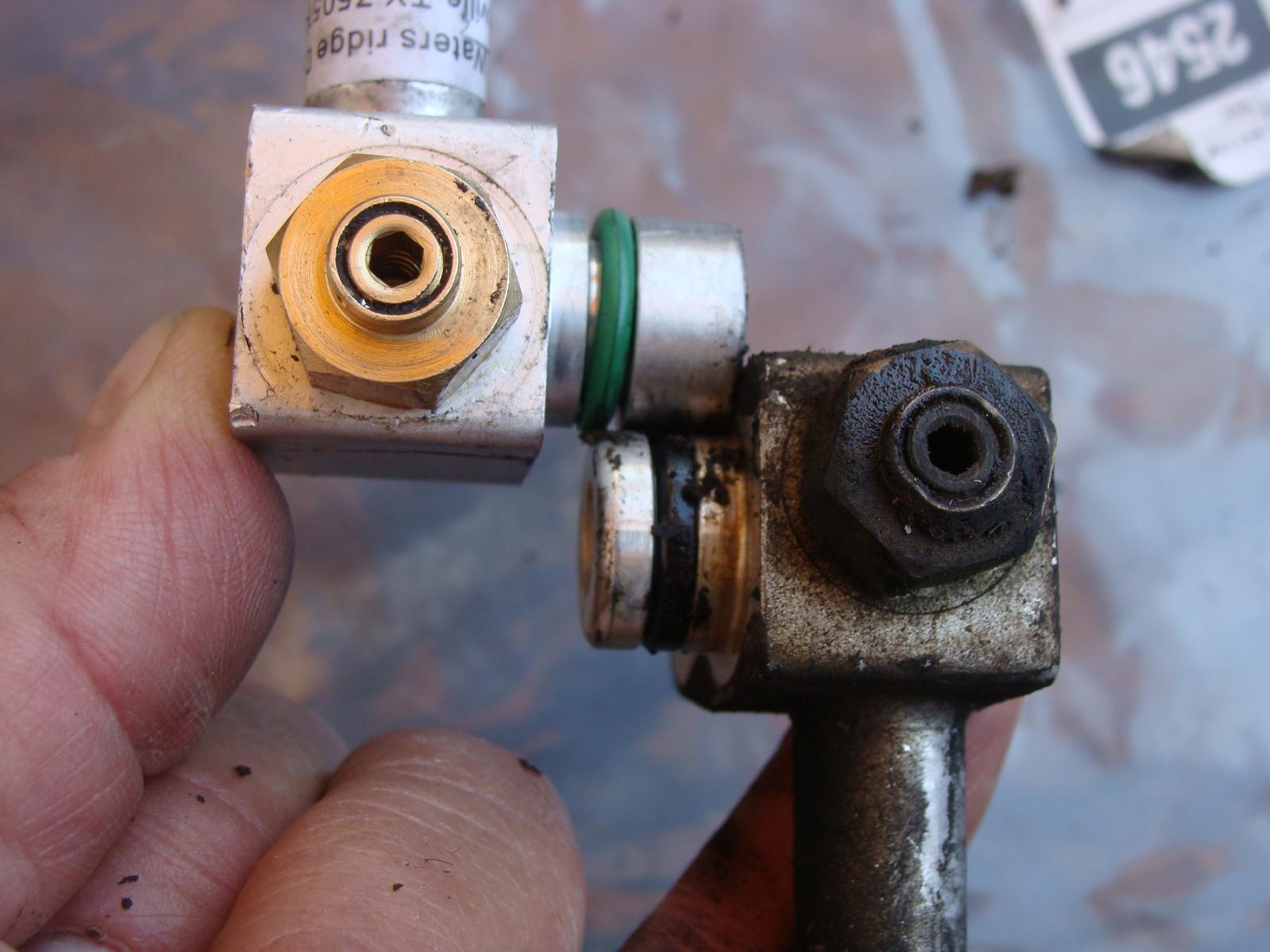

In the second photo, it does look like the flange is deformed, and the o-ring looks rather thin for the groove (in the line) into which it fits. Are you sure it's the correct o-ring?

If the line end in the second photo is too far gone and won't tighten up enough, you'll have to replace the entire line. You said that doing so isn't feasible, though. Is that because it's too difficult to R&R or is it because the line is too expensive?

One tip from the pros is to use Nylog Blue, sparingly, on every o-ring and threaded flare connection when reassembling the system components to help ensure leak-free joints.

Member – MACS (Mobile Air Climate Systems Association)

Thankful for the responses you have received? Please consider making a monetary donation to this Forum.

Thankful for the responses you have received? Please consider making a monetary donation to this Forum.

Re: Leak

I'm going to throw my 2 cents in here, since I also have a 2004 Frontier; mine is 4-cylinder, 5-speed and most of the 2004 trucks were V6 and automatics. I replaced the compressor, condenser, and drier on mine (and backflushed the high pressure lines with solvent) after the AC compressor seized up in 2018 at about 104K miles. I didn't have any issues such as were posted here.tnfarmboy wrote: ↑Sat May 28, 2022 8:04 pm I just replaced the compressor, and condenser, etc on my 2004 Frontier. It wouldn’t hold a vacuum so I put a little freon in and could immediately hear the leak. The high pressure line was loose at the New condenser, I could move it, not a lot, but a little is too much. So, I bought a new low side line with the flange thinking the old one was worn. Well, same thing. The mating surface on the new condenser looks fine, haven’t put a straight edge on it though. At the beginning, I put new O-Rings on both lines, same size, different color, lol. I can’t tell if that flange on the high line is crushed any. Replacing that high pressure line is not feasible. I’ve got some ideas, but they are redneckish. Otherwise, I’m pretty much lost here. Anybody been here? Ideas?

But I also have a 1998 Frontier, same configuration as my 2004, with 270K on it. This one has the factory compressor (now 1 AC clutch shim removed to fix slippage) and other factory parts, but in 2017 I did develop a pinhole in the high pressure line a few years ago. Nissan had discontinued the part, so the only available replacement part (Murray, same part sold to all the big retailers) was aftermarket, and the depth of the fitting into the high side of the compressor was different, and I could not get a seal there. It turned out that the replacement line's fitting was actually different, see photo.

See, the depth of the replacement line was deeper than with the factory line. Facing either spicing/repairing my old, heat-aged factory Arizona line or trying to find a shop to fabricate a new hose for me using my existing end fittings, I ground down the fitting of the replacement line to make it fit, since the O-ring location was in the same place, and that has held up, 5 years now. When I called Murray in Texas, I was told that no one had ever reported this issue before; online reviews of this Murray part were also favorable, so maybe I was "special".

So it is possible that your new replacement parts have different recess depth. I would measure all that for sure, and good luck.

- JohnHere

- Preferred Member

- Posts: 1555

- Joined: Sun May 13, 2018 10:20 am

- Location: South Carolina Upstate - USA

Re: Leak

I wonder whether one or both bores in the new condenser, into which the lines fit, are machined a little too shallow, creating a similar problem to what Cusser discovered.

OP, Cusser has already suggested comparing the depth of the bores in the old and new condensers to ascertain. I agree.

OP, Cusser has already suggested comparing the depth of the bores in the old and new condensers to ascertain. I agree.

Member – MACS (Mobile Air Climate Systems Association)

Thankful for the responses you have received? Please consider making a monetary donation to this Forum.

Thankful for the responses you have received? Please consider making a monetary donation to this Forum.

Re: Leak

Moderator - maybe move this thread to the main "Automotive Air Conditioning Forum" section.

Re: Leak

tnfarmboy - did you purchase the parts through the board sponsor ackits.com 602-233-0090 ?

- JohnHere

- Preferred Member

- Posts: 1555

- Joined: Sun May 13, 2018 10:20 am

- Location: South Carolina Upstate - USA

Re: Leak

Good idea. I'll take care of it.

Member – MACS (Mobile Air Climate Systems Association)

Thankful for the responses you have received? Please consider making a monetary donation to this Forum.

Thankful for the responses you have received? Please consider making a monetary donation to this Forum.

Re: Leak

O-ring in the first picture has chunks missing, I think you are either not lubricating it, or maybe shoving it in too rough.

Re: Leak

Thanks for the replies! It will probably be Tuesday before I get back to it. The HVAC store will be open then too, so I’ll pick up some Nylog. I’d never heard of it. I’ll use a little bit on both lines and even that sensor, since I’ll be right there. I haven’t worked on cars for a living, or even a hobby for a long time. This is just one of my personal vehicles.

The new condenser is what changed, so it only makes sense that it’s the problem. Looking at that first picture, it looks like the hose flange was up against that fitting. I thought about the bore diameter being too big, but didn’t check it out. The bore diameter and depth is the first thing I’ll check. And hope it’s just a little shallow, so I can just file down the hose end some. My thought on that is: stick an ac oil soaked piece of of clean shop rag in there, not too far lol, file and then pull it out with tweezers.

Now that I think about it though, If the line was bottomed out in the condenser and up against the fitting, it wouldn’t be movable...holy crap, I just need to think about something else right now LMAO!!!!

As for the O-ring, it looked the same size to me. I’ll post a picture. When I go to the HVAC store I’ll have one with me and hopefully they will have a fatter one, just in case...the set I have doesn't.

The original problem was: When I turned on the ac the clutch engaged, but the pressures didn’t change. It had been working fine, then it wasn’t. I didn’t do any diagnosis after that, just bought parts. I read up, well, youtubed up lol and found that you can’t flush newer condensers. Thus the new condenser with built on receiver/dryer, from “Rock Auto.” Didn’t know about this forum until problems arose.

I’ll let you know what I find. Hopefully a happy ending and not just more questions lol.

Thanks again for your input!!

DD

The new condenser is what changed, so it only makes sense that it’s the problem. Looking at that first picture, it looks like the hose flange was up against that fitting. I thought about the bore diameter being too big, but didn’t check it out. The bore diameter and depth is the first thing I’ll check. And hope it’s just a little shallow, so I can just file down the hose end some. My thought on that is: stick an ac oil soaked piece of of clean shop rag in there, not too far lol, file and then pull it out with tweezers.

Now that I think about it though, If the line was bottomed out in the condenser and up against the fitting, it wouldn’t be movable...holy crap, I just need to think about something else right now LMAO!!!!

As for the O-ring, it looked the same size to me. I’ll post a picture. When I go to the HVAC store I’ll have one with me and hopefully they will have a fatter one, just in case...the set I have doesn't.

The original problem was: When I turned on the ac the clutch engaged, but the pressures didn’t change. It had been working fine, then it wasn’t. I didn’t do any diagnosis after that, just bought parts. I read up, well, youtubed up lol and found that you can’t flush newer condensers. Thus the new condenser with built on receiver/dryer, from “Rock Auto.” Didn’t know about this forum until problems arose.

I’ll let you know what I find. Hopefully a happy ending and not just more questions lol.

Thanks again for your input!!

DD

- Attachments

-

- O-Rings.jpg (186.06 KiB) Viewed 3357 times

Re: Leak

Those are radial O-ring glands, whether or not the pilot is bottoming out inside the bore doesn't make a difference to their ability to seal. Even if they were sitting 3mm away from from bottoming out, they should still seal (if everything else is correct), I think your O-rings are wrong size or damaged. The condenser fitting bores could also be damaged.

Also looks like that liquid line fitting is pretty jacked up, was it maybe pinched and now it's leaking out of the aluminum pipe?