System design with GMA6 Compressor

Moderators: bohica2xo, Tim, JohnHere

-

Savannarx3

- Posts: 4

- Read the full article

- Joined: Sun Aug 14, 2016 7:02 pm

System design with GMA6 Compressor

Hi guys,

I am getting ready to put air into my old 1950s Chevy. I plan to use a GMA6 compressor simply because it looks like it's meant to be there. Sanden units always stick out like a sore thumb to me, and with the GMA6 I can utilize factory brackets. Unlike most, I loathe and detest the look of bracketry and mounting systems like the Allan Grove items.

So for the remainder of the system, which is for the most part hidden, I can use modern components for increased performance. The system will run on R134a. I plan to use the biggest parallel flow condenser that will fit my application. Pipework is not an issue and will be custom made, mostly using hard lines where possible to be neat and hidden.

My questions are regards opinions on how to regulate gas flow. Taking into account the use of the GMA6 compressor, what system would be better, a TX (expansion) valve system with receiver drier, or an orifice tube and accomulator system? Would you recommend a POA or VIR to control flow and avoid evaporator flooding? My plan for the interior components was to use a complete factory HVAC unit from a late model system for a large SUV with block style expansion valve of at least 2.0 tons with a receiver drier, but I'm not sure how well this would work with the GMA6 which moves larger volumes of gas than a Sanden or Denso.

Any input on the design of this system would be appreciated.

Oh and before you go telling me to use a Vintage Air or other such unit without trying to reinvent the wheel, you should know that my car is right hand drive. All of the off the shelf A/C systems for old cars are configured for left hand drive, and are not suitable for my application.

I am getting ready to put air into my old 1950s Chevy. I plan to use a GMA6 compressor simply because it looks like it's meant to be there. Sanden units always stick out like a sore thumb to me, and with the GMA6 I can utilize factory brackets. Unlike most, I loathe and detest the look of bracketry and mounting systems like the Allan Grove items.

So for the remainder of the system, which is for the most part hidden, I can use modern components for increased performance. The system will run on R134a. I plan to use the biggest parallel flow condenser that will fit my application. Pipework is not an issue and will be custom made, mostly using hard lines where possible to be neat and hidden.

My questions are regards opinions on how to regulate gas flow. Taking into account the use of the GMA6 compressor, what system would be better, a TX (expansion) valve system with receiver drier, or an orifice tube and accomulator system? Would you recommend a POA or VIR to control flow and avoid evaporator flooding? My plan for the interior components was to use a complete factory HVAC unit from a late model system for a large SUV with block style expansion valve of at least 2.0 tons with a receiver drier, but I'm not sure how well this would work with the GMA6 which moves larger volumes of gas than a Sanden or Denso.

Any input on the design of this system would be appreciated.

Oh and before you go telling me to use a Vintage Air or other such unit without trying to reinvent the wheel, you should know that my car is right hand drive. All of the off the shelf A/C systems for old cars are configured for left hand drive, and are not suitable for my application.

Re: System design with GMA6 Compressor

Which engine is in the car?

The A6 was never designed to operate as a cycling clutch unit. It is from the TXV + POA valve era.

RHD - where are you located?

The A6 was never designed to operate as a cycling clutch unit. It is from the TXV + POA valve era.

RHD - where are you located?

-

ice-n-tropics

- Posts: 163

- Joined: Sat Apr 23, 2016 3:40 pm

Re: System design with GMA6 Compressor

3X

Problems with A6 are weight of monster iron & steel 12.6 in3, high parasitic torque draw, heavy mounts causing undesirable coil spring height reduction on mounting side, borderline shaft seal with some refrigerant /lube combos, excessive pressure due to limited condenser real estate, front bumper dip when clutch engages, space eater, etc.

The 8.42 in3 (138cc) SD5H14 is a great system balance match for the heat rejection coil face area and a enhanced radiator fan.

A hang on under center dash evaporator is another good match. First prize would be a old MARK IV Monitor with centered controls off e bay. Vintage Air has a unit with LH controls. I have a hang on A/C evaporator with RH controls that's available or you can shop Japan.

hotrodac

Problems with A6 are weight of monster iron & steel 12.6 in3, high parasitic torque draw, heavy mounts causing undesirable coil spring height reduction on mounting side, borderline shaft seal with some refrigerant /lube combos, excessive pressure due to limited condenser real estate, front bumper dip when clutch engages, space eater, etc.

The 8.42 in3 (138cc) SD5H14 is a great system balance match for the heat rejection coil face area and a enhanced radiator fan.

A hang on under center dash evaporator is another good match. First prize would be a old MARK IV Monitor with centered controls off e bay. Vintage Air has a unit with LH controls. I have a hang on A/C evaporator with RH controls that's available or you can shop Japan.

hotrodac

-

Savannarx3

- Posts: 4

- Joined: Sun Aug 14, 2016 7:02 pm

Re: System design with GMA6 Compressor

Thanks for your responses guys.

bohica2xo, here in Australia, in the early 1980s we had local cars with GMA6 compressors running orifice tube / accumulator systems, no POA or VIR. Earlier cars had POA valves, but by the release of the new models in 1979 they were no longer. I assume this setup should work with any A6?

I understand all your points ice-n-tropics, but they are all compromises that I have considered and are willing to take over a Sanden unit that looks 25 years too new for the engine bay. I know no one will see this except me. But I built the car for me, not for anybody else, and aesthetics are a major concern to me.

I have a lot of room up front to fit a big condenser. I will be using an OE unit (not universal) to maximise surface area here, so the only point you made regards operational efficiencies I hope to be negating through this. I am aware of the shaft seal issues and am prepared to work with this, I have overcome them in the past on customers' cars, no reason why I can't again here. The only point you make that I don't understand is this: "front bumper dip when clutch engages." What do you mean by this?

The car is powered by a 327 small block Chevy motor. I don't think that the torque draw will be too much of an issue. Space is not a concern. In fact I want to fill space outboard of the cylinder head to "balance" the look of the motor with the generator (actually a powergen alternator that looks like a generator, again chosen for aesthetics) which is hanging off the other side.

I could maybe be convinced to go with an S6 (Denso type) replacement for the A6. I would choose the S6 simply because it is available in a black casing whereas the PRO6TEN is not available in black. But I'd prefer to use an A6, again this coming down to the simple fact that the modern looking unit will bother me. There is zero chance I'll put a 5H14 or 7H15 on this vehicle, I would live without A/C before I did that.

Under dash A/C is also off the cards. The car is a factory A/C car and has factory dash vents which I have every intention of putting to use. I know adapting an in dash unit from another vehicle is the more difficult option, but I have done my time with under dash units and for this car I want integrated A/C. The road less travelled is the more rewarding one. I'm not looking for the easy way out here.

bohica2xo, here in Australia, in the early 1980s we had local cars with GMA6 compressors running orifice tube / accumulator systems, no POA or VIR. Earlier cars had POA valves, but by the release of the new models in 1979 they were no longer. I assume this setup should work with any A6?

I understand all your points ice-n-tropics, but they are all compromises that I have considered and are willing to take over a Sanden unit that looks 25 years too new for the engine bay. I know no one will see this except me. But I built the car for me, not for anybody else, and aesthetics are a major concern to me.

I have a lot of room up front to fit a big condenser. I will be using an OE unit (not universal) to maximise surface area here, so the only point you made regards operational efficiencies I hope to be negating through this. I am aware of the shaft seal issues and am prepared to work with this, I have overcome them in the past on customers' cars, no reason why I can't again here. The only point you make that I don't understand is this: "front bumper dip when clutch engages." What do you mean by this?

The car is powered by a 327 small block Chevy motor. I don't think that the torque draw will be too much of an issue. Space is not a concern. In fact I want to fill space outboard of the cylinder head to "balance" the look of the motor with the generator (actually a powergen alternator that looks like a generator, again chosen for aesthetics) which is hanging off the other side.

I could maybe be convinced to go with an S6 (Denso type) replacement for the A6. I would choose the S6 simply because it is available in a black casing whereas the PRO6TEN is not available in black. But I'd prefer to use an A6, again this coming down to the simple fact that the modern looking unit will bother me. There is zero chance I'll put a 5H14 or 7H15 on this vehicle, I would live without A/C before I did that.

Under dash A/C is also off the cards. The car is a factory A/C car and has factory dash vents which I have every intention of putting to use. I know adapting an in dash unit from another vehicle is the more difficult option, but I have done my time with under dash units and for this car I want integrated A/C. The road less travelled is the more rewarding one. I'm not looking for the easy way out here.

Re: System design with GMA6 Compressor

You mentioned using hard lines. There is a lot of vibration in the engine compartment nd if it were me, I would use new custom made rubber hoses.

Re: System design with GMA6 Compressor

The A6 was not designed to cycle.

GM "value engineers" did a lot of stupid things to cut corners, the CCOT was one of them. In the world of control systems, the CCOT would be called a "Bang-Bang" system. Wide open or off. The whole A6 CCOT mess did not exist for long.

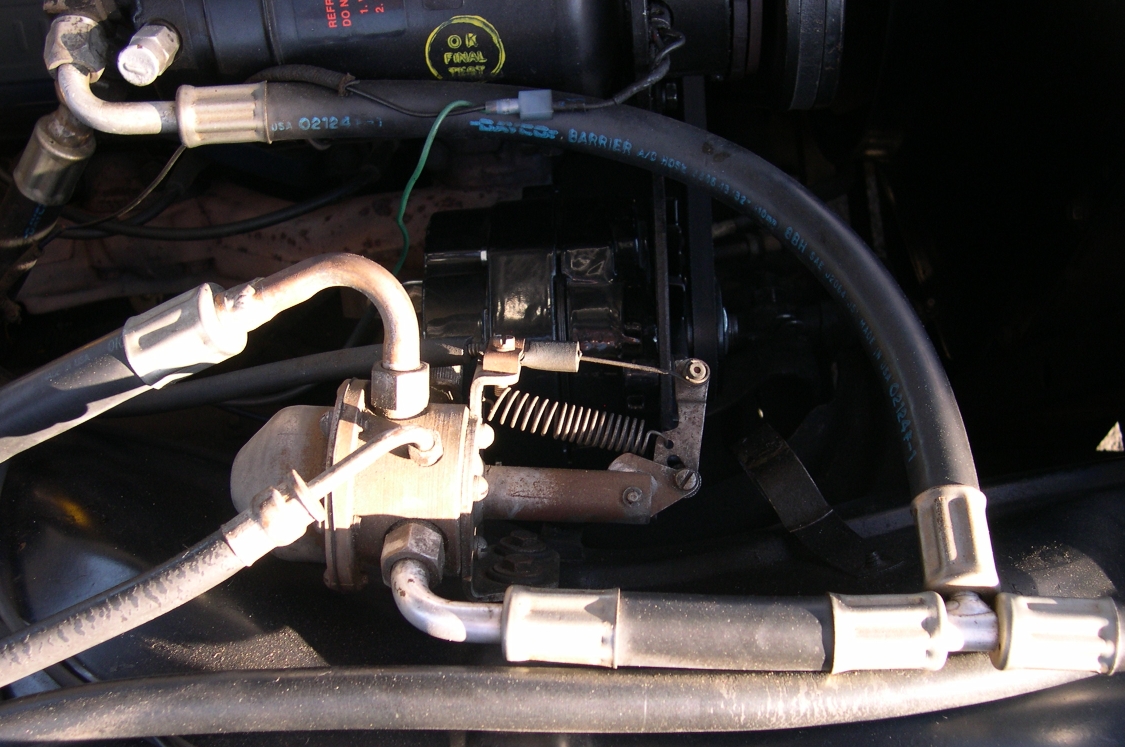

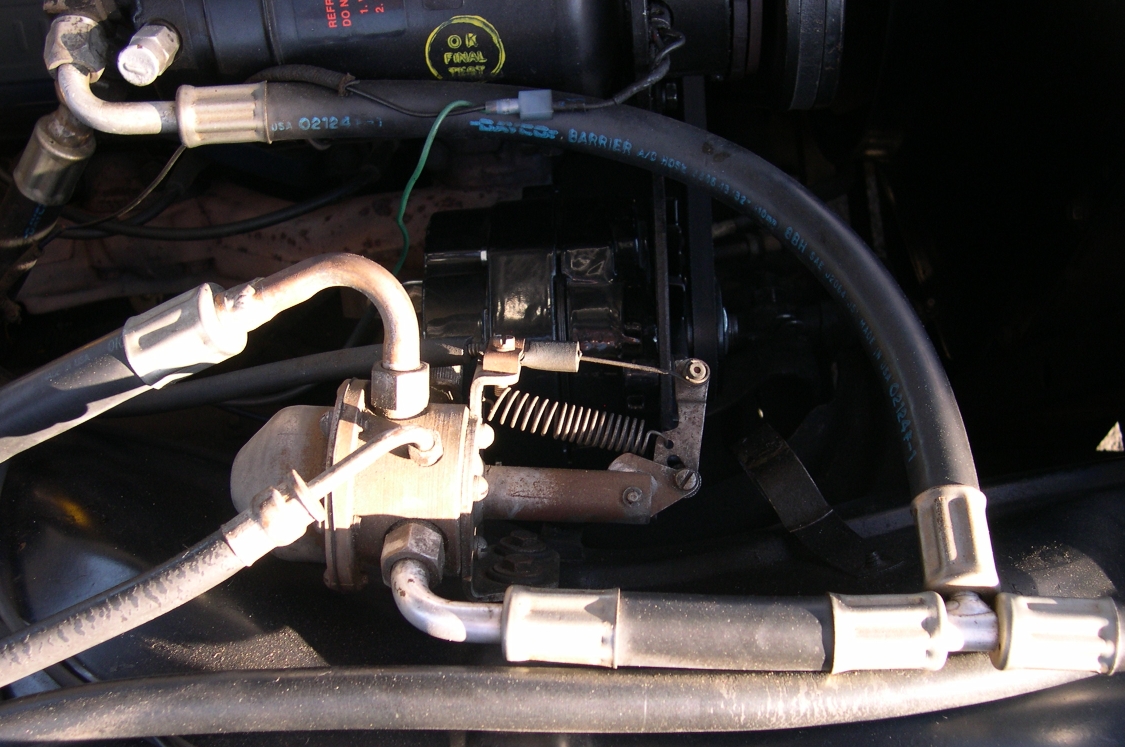

Since you are fixated on OEM looks, you should have an A5,with the Hot Gas bypass valve. Here is a 1959 Cadillac:

You can use a hot gas valve with the A6. They can be rebuilt. Or you could use the pre 1965 STV valve that GM used. '65 & up POA valves are available too.

If you are willing to move ahead to OEM GM from the 1980's, the V5 / V7 will solve the problem. Are you staying with V belts, or going serpentine?

GM "value engineers" did a lot of stupid things to cut corners, the CCOT was one of them. In the world of control systems, the CCOT would be called a "Bang-Bang" system. Wide open or off. The whole A6 CCOT mess did not exist for long.

Since you are fixated on OEM looks, you should have an A5,with the Hot Gas bypass valve. Here is a 1959 Cadillac:

You can use a hot gas valve with the A6. They can be rebuilt. Or you could use the pre 1965 STV valve that GM used. '65 & up POA valves are available too.

If you are willing to move ahead to OEM GM from the 1980's, the V5 / V7 will solve the problem. Are you staying with V belts, or going serpentine?

-

ice-n-tropics

- Posts: 163

- Joined: Sat Apr 23, 2016 3:40 pm

Re: System design with GMA6 Compressor

G'day mate,

Now i get it! You'r trying to avoid a sunburn right arm wilst remaining a purist.

Engagement torque = 50% pumping torque + 50% (or more for iron components) torque to over come rotary moment of inertia. Engagement torque shock causes deceleration which is barely noticable or measurable with a system balanced displacement pump and aluminum pump guts, but A6 is abnormal. Acceleration/power robbing sudden load causes the front bumper to drop a little (think diving into a billabong).

SD508 was introduced in 1971

The 55 chevy factory A/C had a A-5 compressor from Frigidair/Harrison which was later made in Asia in a lighter weight version. The A means axial pistons. Had A-5 on my red 59 Impala and yeah, I replaced the shaft seal.

The A-6 was introduced in 1962. I worked on a Opal GT (where I saw the body made in Chausson near Paris) which had a modified A-6 with increased (shaved pistons) TDC clearance to reduce torque. Corvair had a CCW A-6 as also used on train locamotives.

hotrodac

Now i get it! You'r trying to avoid a sunburn right arm wilst remaining a purist.

Engagement torque = 50% pumping torque + 50% (or more for iron components) torque to over come rotary moment of inertia. Engagement torque shock causes deceleration which is barely noticable or measurable with a system balanced displacement pump and aluminum pump guts, but A6 is abnormal. Acceleration/power robbing sudden load causes the front bumper to drop a little (think diving into a billabong).

SD508 was introduced in 1971

The 55 chevy factory A/C had a A-5 compressor from Frigidair/Harrison which was later made in Asia in a lighter weight version. The A means axial pistons. Had A-5 on my red 59 Impala and yeah, I replaced the shaft seal.

The A-6 was introduced in 1962. I worked on a Opal GT (where I saw the body made in Chausson near Paris) which had a modified A-6 with increased (shaved pistons) TDC clearance to reduce torque. Corvair had a CCW A-6 as also used on train locamotives.

hotrodac

-

Savannarx3

- Posts: 4

- Joined: Sun Aug 14, 2016 7:02 pm

Re: System design with GMA6 Compressor

Thanks again for your responses guys.

I am aware that the factory compressor is an A5, as I have the original here. I am choosing to use the A6 for a few different reasons. Firstly, and foremost, as noted the car has been converted by myself to right hand drive. This includes a conversion of the accessories on the front of the motor, meaning I am placing the generator onto the right side, like the early 55-59 Corvettes ran, and plan to put the compressor onto the left side. This makes sense as this is the side the evaporator will be on, so less hose work in the engine bay. This means converting the cumbersome and heavy mount to the other side of engine, a not uncomplicated task. It also places the compressor above the valve cover, which I don't want to do, I want it outboard. Plenty of room there, and offers better serviceability of the engine. I will use a combination of factory A6 brackets for the short water pump and custom made pieces to achieve the compressor mounting in the correct plane for belt alignment. I am of course staying with V belts.

The A5 I have also will require a rebuild, as it has been unused for at least three decades, probably more. Doing this in Australia would be impractical at best, and no doubt cost prohibitive. An A6 looks practically the same, and was mounted from 1962 onwards on these SBC engines, so it looks right, if not correct, in the engine bay. Any Sanden or other compressor will look like an added on afterthought, and is just not the look I am going for on this car. I am prepared to compromise some efficiency for the appearance that I want. If I wanted function over form I would just give up and drive a Camry.

You guys have basically answered my questions, and I thank you for that. I know now that a later model block TX & evaporator won't be what I want, nor will a CCOT system. I will put a POA valve into the mix and get things working that way. Hard lines are just fine in an engine bay when properly built and fixed. It will only be the liquid line after all. So much neater than hoses running everywhere. Again, I am not looking for the easy way out with this project.

I'm not really a purist to be honest. I just like things to look good. I like my modifications to be subtle enough as to go unnoticed by most. For another example of what I am doing to achieve this, I will be using a Dodge Nitro condenser with an integral oil cooler. This fits the space very nicely, puts the functional condenser surface area at larger than the Vintage Air condenser, and it gives me an external oil cooler for the 700R4 gearbox that I installed in the vehicle, meaning less mess for another cooler. This is far from stock in appearance, but should be as close to invisible as any condenser would be once installed. Sanden compressors stick out like dogs proverbials, they're just not the look I want. Same with under dash units inside, if I can't build myself a nice invisible integrated unit I don't deserve to have A/C in the car!

I am aware that the factory compressor is an A5, as I have the original here. I am choosing to use the A6 for a few different reasons. Firstly, and foremost, as noted the car has been converted by myself to right hand drive. This includes a conversion of the accessories on the front of the motor, meaning I am placing the generator onto the right side, like the early 55-59 Corvettes ran, and plan to put the compressor onto the left side. This makes sense as this is the side the evaporator will be on, so less hose work in the engine bay. This means converting the cumbersome and heavy mount to the other side of engine, a not uncomplicated task. It also places the compressor above the valve cover, which I don't want to do, I want it outboard. Plenty of room there, and offers better serviceability of the engine. I will use a combination of factory A6 brackets for the short water pump and custom made pieces to achieve the compressor mounting in the correct plane for belt alignment. I am of course staying with V belts.

The A5 I have also will require a rebuild, as it has been unused for at least three decades, probably more. Doing this in Australia would be impractical at best, and no doubt cost prohibitive. An A6 looks practically the same, and was mounted from 1962 onwards on these SBC engines, so it looks right, if not correct, in the engine bay. Any Sanden or other compressor will look like an added on afterthought, and is just not the look I am going for on this car. I am prepared to compromise some efficiency for the appearance that I want. If I wanted function over form I would just give up and drive a Camry.

You guys have basically answered my questions, and I thank you for that. I know now that a later model block TX & evaporator won't be what I want, nor will a CCOT system. I will put a POA valve into the mix and get things working that way. Hard lines are just fine in an engine bay when properly built and fixed. It will only be the liquid line after all. So much neater than hoses running everywhere. Again, I am not looking for the easy way out with this project.

I'm not really a purist to be honest. I just like things to look good. I like my modifications to be subtle enough as to go unnoticed by most. For another example of what I am doing to achieve this, I will be using a Dodge Nitro condenser with an integral oil cooler. This fits the space very nicely, puts the functional condenser surface area at larger than the Vintage Air condenser, and it gives me an external oil cooler for the 700R4 gearbox that I installed in the vehicle, meaning less mess for another cooler. This is far from stock in appearance, but should be as close to invisible as any condenser would be once installed. Sanden compressors stick out like dogs proverbials, they're just not the look I want. Same with under dash units inside, if I can't build myself a nice invisible integrated unit I don't deserve to have A/C in the car!

Re: System design with GMA6 Compressor

Since you are making brackets, and this is not a points car you should use a V5 compressor:

http://www.ackits.com/index.php?route=p ... t_id=51772

Paint it black and it will resemble the A5. It is a GM unit, and includes evaporator pressure control. No POA needed.

Sell the A5 - somebody needs it for an actual restoration. Any chance you still have the hot gas valve?

.

http://www.ackits.com/index.php?route=p ... t_id=51772

Paint it black and it will resemble the A5. It is a GM unit, and includes evaporator pressure control. No POA needed.

Sell the A5 - somebody needs it for an actual restoration. Any chance you still have the hot gas valve?

.

-

ice-n-tropics

- Posts: 163

- Joined: Sat Apr 23, 2016 3:40 pm

Re: System design with GMA6 Compressor

G'day Mate,

FYI: OEM A/C engineers measure "engagement bump" on a dyno with a dial indicator touching the underside of the front bumper. The scroll and external control compressors are first prize for this fully objective evaluation.

Vintage Air book "How to Air condition your Hot Rod" for DIY A/C installations in Rods covers several GEN IV integrated HAC in-dash installations, (but w/o OSA/fresh air). A-6 would be a over kill on capacity for a GEN IV unless the A-6 pistons are machined like the OPAL GT.

The steering column could be challenging for in dash location unless you have electric steering. My experience with RH steering mechanisms interfering with the HVAC is a PITA.

Tim's older "band of brothers" dealt with several POA 134a conversions where evaporator icing vs. cooling pull down were problematic.

Another option that I did on a BLAZER was to fab a central console A/C evap with forward air discharge into dash louvers

Hope to see progress pictures.

hotrodac

FYI: OEM A/C engineers measure "engagement bump" on a dyno with a dial indicator touching the underside of the front bumper. The scroll and external control compressors are first prize for this fully objective evaluation.

Vintage Air book "How to Air condition your Hot Rod" for DIY A/C installations in Rods covers several GEN IV integrated HAC in-dash installations, (but w/o OSA/fresh air). A-6 would be a over kill on capacity for a GEN IV unless the A-6 pistons are machined like the OPAL GT.

The steering column could be challenging for in dash location unless you have electric steering. My experience with RH steering mechanisms interfering with the HVAC is a PITA.

Tim's older "band of brothers" dealt with several POA 134a conversions where evaporator icing vs. cooling pull down were problematic.

Another option that I did on a BLAZER was to fab a central console A/C evap with forward air discharge into dash louvers

Hope to see progress pictures.

hotrodac